Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

WORLDWIDE

The direct use of coal as a feedstock (not just energy) is particularly significant in China, where coal is used extensively in coal to gasification plants to produce chemicals such as methanol, ammonia, and polyvinyl chloride (PVC). In 2017, China's chemical industry alone used about 180 million tonnes of coal as feedstock, which constituted about 5% of China’s total coal use that year.

China is unique in its heavy reliance on coal for chemical manufacturing, accounting for a large share of global coal-to-chemicals production. For example, 89% of methanol and 76% of ammonia production in China is coal-based, and producing 1 tonne of methanol from coal requires about 2.7–3 tonnes of coal.

India is also expanding its coal gasification capacity, with government plans to gasify 100 million tonnes (MT) of coal annually by 2030

In contrast, other major chemical-producing regions (Europe, North America, Middle East) primarily use natural gas or crude oil as feedstocks rather than coal.

UK

There is negligible or close to zero coal gasification industry in the UK as of 2025: over the past 20 years, gasification projects have focused on waste or biomass, rather than coal.

WORLDWIDE

Global brick production was estimated at 2.18 billion tonnes in 2020, resulting in approximately 500 million tonnes of CO2e (1% of current global GHG emissions). Brick production could rise to 3.35 billion tonnes by 2050. Approximately 375 million tonnes of coal are used globally per year in brick production, mostly as fuel to heat kilns. Research indicates that coal is added to clay bricks at rates of 1–15% by weight of the clay mixture.

Switching from coal to alternative fuels, together with more efficient kilns, will lead to reduced CO2 emissions.

UK

Heating brick-firing ovens in the UK uses a mix of natural gas, electricity, coal and coke, diesel and LPG fuels. The primarily for use of coal in bricks, though is as an additive to colour it. According to coal mining company, Energybuild Ltd, UK brickworks consume approximately 70,000 tonnes per year of additives, which includes coal.

Annual tonnage of anthracite coal used by the UK brickmaking industry is not made public but the proportion used within the UK generally falls within the range of 1–5% of the brick mix by weight, depending on the desired product characteristics. This contributes to the high emissions released from the raw brick materials upon firing.

WORLDWIDE

Activated carbon is typically made from charcoal (wood) and is a common filtration medium in water treatment systems. It can be manufactured from other sources, with anthracite coal being a common source. Alternatives include nutshells. These sources are first processed into activated carbon through high-temperature treatment to create a porous structure suitable for adsorption

The global market for coal-based activated carbon was valued at approximately USD 4.44 billion in 2024, with demand driven by applications in air purification and water treatment.

Alternatives to the traditional sand/activated carbon dual medium to filter water include glass, garnet, magnetite, and other materials.

UK

The exact annual tonnage of anthracite coal used by the UK water filtration industry is not made public but it does use both domestically mined and imported coal.

WORLDWIDE

The cement industry consumes around 4% of global coal production, which amounts to approximately 330 million tonnes per year. Most of this coal is combusted to generate the heat required to fire the kilns to about 1450c to create the chemical reaction that produces cement. Roughly 0.5 tonnes of coal are needed to produce 1 tonne of cement.

Coal in cement production is primarily used as a fuel to heat kilns, but it can also serve as a minor feedstock in the form of fly-ash for introducing carbon into the clinker. Fly ash is used as a substitute for Ordinary Portland Cement (OPC) used in cement production, and can actually increase the concrete durability, reducing the need for replacement. By using waste coal fly ash as a substitute for kiln-based ‘clinker’ in cement production, the cement industry can significantly reduce its carbon footprint. Post-consumer waste can also be used to both reduce the coal used to heat the kilns and to produce the fly-ash input, helping to decouple coal from the cement industry.

UK

Over 95% of UK concrete is produced in the UK. UK cement manufacture has begun switching from traditional fossil fuels such as coal and petcoke to the use of waste, waste biomass and waste part- biomass fuels. These alternative fuels now account for 43 per cent of the fuel used (2020), replacing the equivalent of half a million tonnes of coal every year. This means 1.16 million tonnes of coal would be used if it weren’t for replacement fuels, and 660 thousand tonnes of coal is still used in UK cement manufacture.

UK carbon dioxide emissions from concrete and cement were 7.3 million tonnes in 2018; around 4.4 million tonnes of this was ‘process emissions’ from clinker production, 2.2 million tonnes from fuel combustion and the remainder from electricity use and transport. This puts direct and indirect emissions at 53% lower than 1990. UK concrete and cement accounted for around 1.5% of UK carbon dioxide emissions in 2018. UK Government research indicates that the elimination of fossil fuels should be possible with no negative impact on clinker quality, kiln stability or build-up issues, but plant-specific modelling would be required. If coal used as a fuel and clinker input was switched for alternatives at all cement plants in the UK, the annual CO2 saving would amount to over 2 million tonnes of CO2.

Coming soon!

Coming soon!

The direct use of coal as a feedstock (not just energy) is particularly significant in China, where coal is used extensively in coal to gasification plants to produce chemicals such as methanol, ammonia, and…

This nature was photographed around 50 metres from the edge of the Glan Lash opencast coal mine in Ammanford, South Wales. It shows the thriving ecosystems surrounding the Glan Lash opencast coal mine which has remained dormant since 2019…

In February, CAN gave oral testimony to the Climate Change, Energy, and Infrastructure Committee (CCEIC) on the Disused Mine and Quarry Tips (Wales) Bill…

Coal Action Network was invited to attend Westminster where we gave evidence to the Welsh Affairs Committee in their inquiry about the environmental and economic legacy of Wales’ industrial past, alongside Friends of the Earth Cymru. This inquiry was opened in…

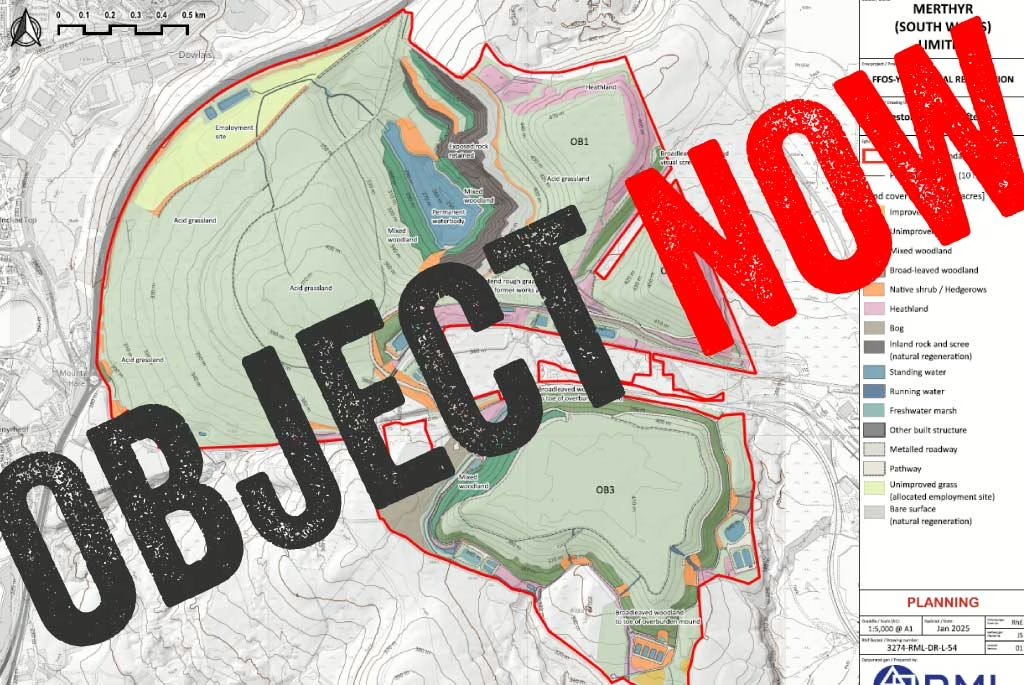

16 years of opencast coal mining in Ffos-y-fran has generated colossal overburden mounds, also known as slag heaps or coal tips. There are three coal tips, with the third being the largest, and cumulatively accounting for 37 million cubic metres of colliery spoil, rocks, and soil…

We were invited for the second time to give oral evidence to the Climate Change, Environment, and Infrastructure Committee of the Welsh Parliament (Senedd) on 05th February 2025. We shared the panel with Haf, Director of FOE Cymru, to provide our opinion on the weaknesses, strengths…

Merthyr (South Wales) Ltd mined for over a year illegally after planning permission for the Ffos-y-fran opencast coal mine ended in September 2022. During that year, it made record-breaking profits due to sanctions on Russia and other factors driving up the price of coal. But rather than using some of the profits from that ill-gotten coal…

MSW claims “It was established that there are insufficient funds available to achieve the 2015 restoration strategy and therefore an alternative scheme is required.” (EIA Scoping Report, July 2024)… To our knowledge, there has been no evidence submitted by MSW that it cannot fund the full restoration it is contracted to undertake…

The UK Government launched a consultation on a limited review of the National Planning Policy Framework (NPPF) for 8 weeks from 30 July to 24 September 2024. The NPPF is an influential document that shapes planning decisions and priorities across England. It is periodically updated by the Government, following a public consultation…